Introduction

Fashion design is an intricate and creative process that involves both technical skills and artistic vision. Two primary methods of creating garments are draping and pattern making, each offering distinct approaches to garment construction. While both methods are integral to the design process, they are based on different techniques, tools, and approaches. This article will explore the key differences, advantages, challenges, and applications of draping and pattern making, offering a comprehensive understanding of these essential techniques in fashion design.

Draping in Fashion Design

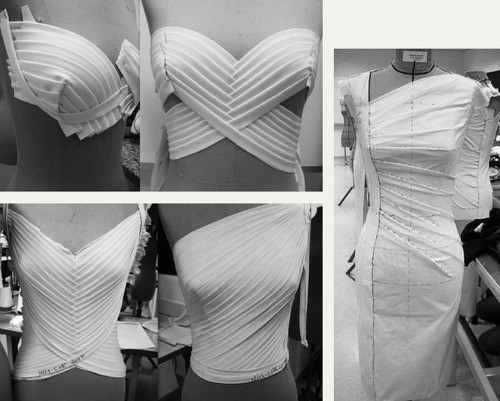

Draping is a technique that involves manipulating fabric directly on a dress form or mannequin to create the desired garment shape. This process allows designers to work intuitively with fabric, letting the material fall and shape itself around the form. Draping is an organic, hands-on method that gives designers immediate feedback and the freedom to explore their ideas in real-time.

Process of Draping

The process of draping typically begins with selecting a fabric that is appropriate for the design and intended garment. The fabric is then pinned, tucked, and pleated onto a dress form, allowing the designer to see how the material interacts with the body. Adjustments are made as needed, creating a three-dimensional representation of the design. After achieving the desired look, the designer can mark key lines, such as the seams, darts, and grainlines, which will then be transferred to paper.

Draping is often used to experiment with shapes, volume, and textures. It is a method that emphasizes creativity, intuition, and the tactile relationship between fabric and form. Many fashion designers use draping when designing couture or one-of-a-kind garments, as it provides a direct connection to the material and allows for more expressive and detailed work.

Advantages of Draping

- Creativity and Flexibility: Draping allows for a more freeform, exploratory approach. Designers can instantly visualize their ideas and make adjustments as they go.

- Three-Dimensional Exploration: Draping provides a tactile understanding of how fabric behaves on the body, making it easier to experiment with volume, texture, and silhouette.

- Sculptural Designs: Draping is especially beneficial for creating complex, sculptural designs that require intricate shaping or folds, as it allows the designer to manipulate the fabric in real-time.

- Couture and Customization: Since draping involves direct interaction with the fabric and the dress form, it is ideal for creating bespoke garments or couture pieces tailored to an individual’s measurements.

Challenges of Draping

- Time-Consuming: Draping requires a hands-on, meticulous approach, which can be time-intensive, especially when working with complex designs.

- Fabric Constraints: The type of fabric used in draping plays a significant role in the process. Some fabrics may not respond well to certain techniques, limiting the designer’s choices.

- Skill and Expertise: Draping requires a high level of skill and an intuitive understanding of how fabrics behave, making it a technique that takes time to master.

- Limited Repeatability: While draping allows for one-of-a-kind pieces, it can be difficult to reproduce the same design consistently. The process can be less suited for mass production or creating a standardized garment.

When is Draping Used?

Draping is most commonly used in high-end fashion, such as couture and bespoke tailoring, where each piece is unique and requires precision in its fit and construction. It is also a favored method for creating experimental, avant-garde designs where a high degree of creativity and three-dimensionality is essential.

Pattern Making in Fashion Design

Pattern making, in contrast to draping, involves creating a two-dimensional blueprint or template from which a garment can be constructed. This method uses flat paper patterns that represent the different parts of a garment (such as the front, back, sleeves, and collars). These patterns are drafted based on precise measurements and construction techniques, allowing for the replication of designs on a large scale.

Process of Pattern Making

Pattern making typically begins with the designer’s sketch or concept, which provides the foundation for the garment’s design. The designer or pattern maker uses the measurements of the body to create a flat pattern, drafting the basic shapes and elements that will later be sewn together. After the initial pattern is drafted, it is tested by making a muslin or sample garment, which is then fitted to the model or dress form.

Once adjustments have been made, the final pattern is produced, and the garment can be constructed using the correct fabric. Unlike draping, pattern making is more focused on precision, measurement, and repeatability. Patterns can be stored, reused, and graded for different sizes, making it ideal for ready-to-wear collections and mass production.

Advantages of Pattern Making

- Precision and Consistency: Pattern making allows for highly accurate garment construction. Patterns are based on measurements and standardized designs, ensuring that each piece fits properly and is reproducible.

- Efficiency: Once a pattern has been created, it can be used to quickly replicate a design, making it ideal for mass production and creating multiple garments.

- Scalability: Pattern making is ideal for ready-to-wear and commercial fashion, where designs need to be scaled to various sizes and manufactured in large quantities.

- Reproducibility: Patterns can be stored and reused for future collections or designs, making it easier to maintain consistency across multiple garments or product lines.

Challenges of Pattern Making

- Less Creative Freedom: Compared to draping, pattern making is more rigid, relying on measurements and templates. Designers may have less room to experiment and explore freeform shapes.

- Complexity: While the process is highly precise, pattern making can be complex, requiring detailed knowledge of garment construction, fitting, and pattern grading.

- Requires Experience: Creating accurate patterns that fit well and represent the designer’s vision requires a high level of skill, particularly when drafting for complex designs or non-standard body shapes.

When is Pattern Making Used?

Pattern making is essential in the production of ready-to-wear collections, mass-produced garments, and designs that need to be replicated across different sizes. It is the primary method used in commercial fashion, where efficiency, consistency, and scalability are crucial. Pattern making is also integral to the production of basic garments, such as shirts, trousers, and dresses, which require accuracy in fit and construction.

Draping vs. Pattern Making: Key Differences

While both draping and pattern making serve similar goals—creating garments that are well-constructed and flattering to the wearer—there are key differences between the two methods in terms of approach, technique, and outcomes.

- Approach:

- Draping is an intuitive, hands-on method where the designer works directly with fabric to create the garment on a dress form. It is more fluid and creative.

- Pattern making is a precise, structured method that involves drafting a flat, two-dimensional pattern based on measurements, which can then be replicated and mass-produced.

- Creativity:

- Draping allows for more creativity and exploration. The designer can experiment with shapes, textures, and volumes, responding immediately to how the fabric behaves.

- Pattern making is more rigid and focused on technical accuracy. While it can be creative, the process is more constrained by measurements and standard construction techniques.

- Replicability:

- Draping can be challenging to replicate, especially for complex designs. Since it is a hands-on method, reproducing the same design exactly can be difficult.

- Pattern making is designed for repeatability. Once a pattern is created, it can be used multiple times to produce consistent results.

- Suitability:

- Draping is ideal for creating unique, one-of-a-kind garments, often used in couture or bespoke design where individuality and high-quality construction are key.

- Pattern making is best suited for mass production, ready-to-wear garments, and designs that require precision and consistency across various sizes.

Combining Draping and Pattern Making

In many cases, designers use both draping and pattern making to create their collections. They may start with draping to explore shapes and silhouettes, then transfer the results to a pattern to ensure accuracy and consistency. This hybrid approach allows designers to leverage the strengths of both techniques, blending creativity with technical precision.