Introduction

In modern fashion and outdoor gear, two attributes stand out as crucial: waterproofing and breathability. These two characteristics are essential for ensuring comfort and protection in various environments, especially for those participating in outdoor activities such as hiking, skiing, cycling, or even daily urban commuting. However, the process behind creating fabrics that are both waterproof and breathable involves intricate science, engineering, and a deep understanding of materials.

This article will explore the science and technology behind waterproof and breathable fabrics, how they work, and why achieving a balance between the two is a challenge. We will examine the mechanisms that make these fabrics functional, how they are manufactured, and the advances in material technology that continue to shape the future of performance fabrics.

- What Makes a Fabric Waterproof?

Waterproof fabrics are designed to prevent water from passing through them. This is achieved through several techniques, such as using materials with very tight weaves or treating the fabric with specialized coatings or membranes. But to truly understand waterproofing, it’s important to explore the science of water resistance in fabric.

The Role of Hydrophobic Materials

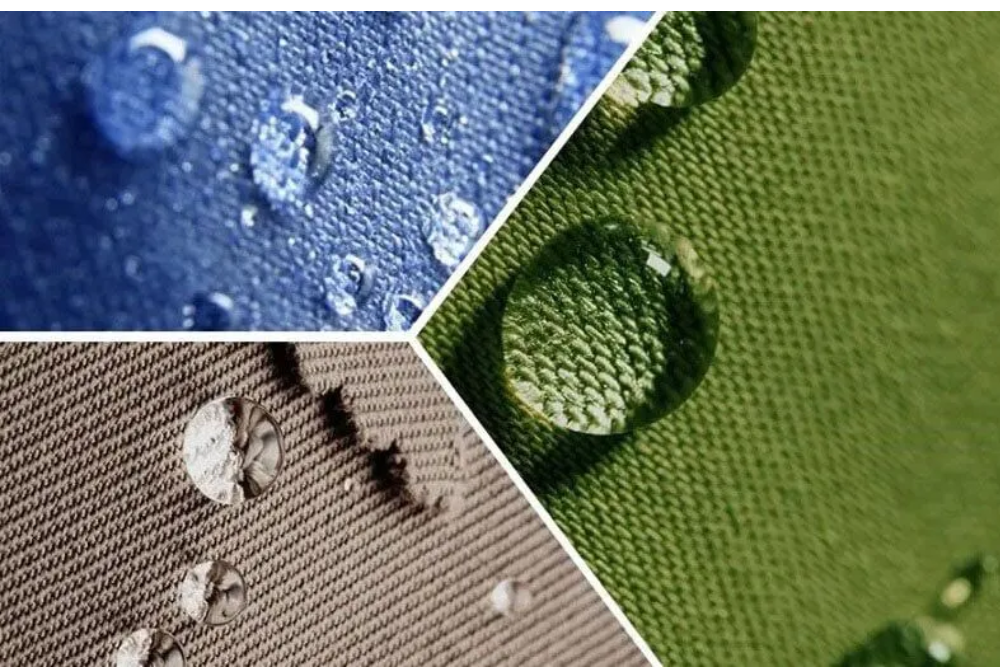

Waterproofing is often achieved through the use of hydrophobic (water-repellent) materials. These materials have low surface energy, which prevents water from adhering to them. When water droplets come into contact with these fabrics, they bead up and roll off instead of soaking through.

Waterproof Coatings

Common waterproof coatings include:

- Polyurethane (PU): PU coatings are often used on lightweight fabrics to create a barrier against water. The polyurethane is applied to the fabric in a thin layer, forming a waterproof membrane.

- Polyvinyl Chloride (PVC): PVC coatings are more durable and can be applied to heavier fabrics. However, they tend to be less flexible than PU coatings.

- Silicone: A more environmentally friendly option, silicone coatings provide excellent waterproofing and can retain their properties even after extensive exposure to moisture.

Waterproof Membranes

Another method of waterproofing involves using a membrane that is laminated or bonded to the fabric. These membranes act as a barrier to water while allowing moisture vapor to pass through. The most well-known example is Gore-Tex, a membrane that is both waterproof and breathable.

Waterproof Ratings (Hydrostatic Head)

Waterproof fabrics are often rated based on the hydrostatic head, a test that measures the amount of water pressure a fabric can withstand before water starts to leak through. For instance, a fabric with a rating of 1,500 mm means it can withstand 1,500 mm of water pressure without leaking.

The higher the hydrostatic head, the more waterproof the fabric is. Fabrics used for jackets and tents, for example, are typically rated between 5,000 mm to 20,000 mm or more.

- The Need for Breathability in Waterproof Fabrics

Breathability refers to a fabric’s ability to allow water vapor (sweat) to escape from the inside while preventing liquid water (rain or snow) from entering. This is especially important in outdoor gear, where sweating can cause discomfort or even lead to hypothermia in cold, wet environments.

The Science of Breathability

Breathability is a critical aspect for garments such as waterproof jackets or pants. Without breathability, moisture from sweat would be trapped inside the garment, leading to discomfort, dampness, and even reduced warmth in cold conditions.

Moisture Vapor Permeability

Breathability is quantified by the Moisture Vapor Transmission Rate (MVTR), which measures the amount of moisture that can pass through a fabric over a certain period, typically expressed in grams per square meter per 24 hours (g/m²/24h). The higher the MVTR, the more breathable the fabric is. This is important because as the body sweats, the moisture needs a way to escape so that the wearer stays dry.

Some breathable fabrics are designed with microporous membranes that allow water vapor molecules to pass through but are too small to let water droplets in. The challenge lies in creating a fabric that allows vapor to escape while blocking liquid water, which is why waterproof fabrics are often associated with certain limitations in breathability.

- The Balance Between Waterproofing and Breathability

The primary challenge in developing waterproof yet breathable fabrics is balancing these two properties. Waterproofing works by creating a barrier that blocks water from entering the fabric, while breathability requires the material to allow moisture vapor to escape. So, how do designers and material scientists achieve a fabric that excels in both properties?

Membrane Technology: Gore-Tex and Other Alternatives

A key solution lies in membrane technology, which provides a structure that blocks water while allowing for some breathability. Membranes are often made of expanded polytetrafluoroethylene (ePTFE) or polyurethane (PU).

Gore-Tex

Gore-Tex is one of the most widely recognized names in breathable waterproof fabric technology. Gore-Tex works by using a microporous membrane that contains billions of microscopic pores per square inch. These pores are small enough to prevent water droplets from passing through but large enough to allow water vapor molecules to escape. This unique structure provides an effective barrier against rain, snow, and wind while maintaining breathability.

The challenge with Gore-Tex and other similar fabrics is that the size of the pores needs to be optimal—too large and water will seep through, too small and moisture vapor cannot escape.

ePTFE Membranes

Expanded polytetrafluoroethylene (ePTFE) is a material that has micropores, similar to Gore-Tex. The key difference is that ePTFE is made by expanding the polymer, which creates a web of very small pores that are water-repellent but still allow vapor to pass through.

ePTFE membranes are used in a wide range of applications, from medical devices to outdoor gear. They provide the advantage of being lightweight, durable, and capable of achieving high levels of waterproofing and breathability.

Permeable Coatings

Coatings can also provide both waterproof and breathable properties, though they are generally less durable and effective compared to membrane-based solutions. Polyurethane coatings are often applied to fabrics to create a waterproof barrier while still allowing some moisture vapor to pass through.

Active Membranes

An emerging field in fabric technology is the development of active membranes. These fabrics change their properties depending on environmental factors like temperature or humidity. For instance, the membrane might open up to allow more breathability when the wearer is sweating or when external conditions become warmer. These smart fabrics are still in the developmental stage but promise to take waterproof and breathable fabrics to a new level of performance.

- Factors That Affect Waterproofing and Breathability

While membrane and coating technologies are key, there are several other factors that can influence the performance of waterproof and breathable fabrics.

Fabric Structure and Construction

The way a fabric is woven or knitted plays a significant role in its overall performance. Tighter weaves are more resistant to water penetration, but they can reduce breathability. On the other hand, looser weaves may allow moisture to pass through but won’t be as effective at blocking water.

Manufacturers often use a combination of fabric layers to balance waterproofing and breathability. For example, a typical waterproof jacket might have an outer shell made of a tightly woven fabric for waterproofing, with an inner lining that enhances breathability.

Environmental Conditions

The effectiveness of waterproof and breathable fabrics also depends on the surrounding environment. Humidity, temperature, and even the wearer’s level of physical activity can all affect how well a fabric performs. For example, when it’s very humid, the moisture vapor from sweat has a harder time escaping, making the fabric feel less breathable.

Garment Fit and Design

The design of the garment itself also affects its ability to be both waterproof and breathable. A poorly fitted jacket might trap moisture inside, making it feel uncomfortable even if the fabric itself is breathable. Ventilation openings, zippers, and strategic seam placements can help facilitate airflow and improve breathability.

- Testing Waterproof and Breathable Fabrics

To ensure that waterproof and breathable fabrics meet the required standards, they undergo rigorous testing in laboratories. Some of the most common tests include:

Hydrostatic Head Test

This test measures the amount of water pressure a fabric can withstand before it begins to leak. The hydrostatic head test is an essential measure for waterproofing and provides a standardized way to compare different fabrics.

MVTR Test

To assess breathability, manufacturers conduct the Moisture Vapor Transmission Rate (MVTR) test. This test measures how much moisture vapor passes through a fabric over a set period of time.

Washing and Durability Tests

Fabrics need to maintain their waterproof and breathable properties after extended use. This means they must undergo durability testing to simulate how they perform after multiple washes, exposure to sunlight, and general wear and tear.

- The Future of Waterproof and Breathable Fabrics

The future of waterproof and breathable fabrics is incredibly promising, thanks to continuous innovations in material science and technology. Advances in nanotechnology and biomimicry (mimicking nature’s design solutions) are already being explored to create even more efficient fabrics. Future fabrics might not only be waterproof and breathable but could also self-clean, respond to environmental conditions, or even monitor the wearer’s health.

In addition, the demand for sustainable fabrics is growing. As consumers become more conscious of the environmental impact of their purchases, there is an increasing focus on producing waterproof and breathable fabrics that are eco-friendly, using materials that are biodegradable or made from recycled resources.